YLM-300

Device description:

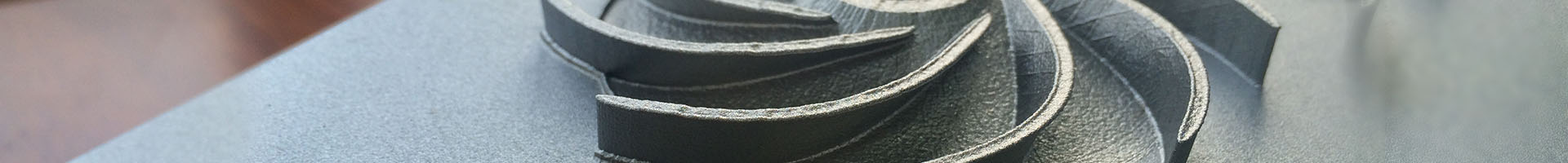

The working cylinder adopts a round design, and the forming chamber achieves the sealing effect at the hydraulic cylinder level. Z resolution of up to 5um;

The forming chamber, the main body and the working cylinder are integrally formed. Stainless steel, aluminum alloy, titanium alloy, cobalt chromium alloy and other metal materials can be directly formed.

Equipment application:

Scientific research, teaching and research and development of new materials;

Aerospace, high-end complex mold manufacturing, digital medical.

YLM-300 technical parameters

Equipment model YLM -300

The forming space is 300mm in the horizontal direction and 300mm in the height direction

Minimum spot size 70UM

The laser power 500W, single-mode fiber laser, the long-term power fluctuation of less than 4%

Laser wavelength 1060-1070nm

Scanning galvanometer, high speed scanning galvanometer, F-theta lens, enclosed optical system, highest scanning speed 7m/s

Quantitative feeding of powder coating mechanism (patent design)

The atmosphere in the shaping chamber controls oxygen content below 100ppm

Inert gas consumption less than 4L/min

Minimum forming wall thickness 100um

Minimum delamination thickness 20um

Forming accuracy + 0.05mm/100mm

Surface roughness of forming parts Ra3.2

Density of formed parts >98%

It can be used as forming materials, such as stainless steel, iron nickel alloy, cobalt chromium alloy, titanium alloy, aluminum alloy, oxygen free copper, high temperature alloy and so on

Equipment power consumption is about 3KW, 220V power supply standard

Equipment dimensions 1800mm, x, 1175mm, x, 2017mm (length, width, height), weight 1.65 tons

Software for forming control software Zflash (Yongnian laser independent development)

Equipment features:

The working cylinder adopts a round design, and the forming chamber achieves the sealing effect of the hydraulic cylinder level, which can effectively prevent leakage of metal powder, improve the service life of the lifting system, and simultaneously reduce the powder loss and pollution;

The forming chamber, the main body and the working cylinder are integrally formed, and the position accuracy is guaranteed by the precision machining center. The accuracy of the Z and the accuracy of the powder feeding are greatly improved, and the minimum resolution of Z is up to 5um;

The sealed powder feeding device in the isolated atmosphere will not add oxygen to the metal powder during the forming process, and will be suitable for some active metal materials of Yu Chengxing

A controlled quantitative powder feeding structure is adopted to replace the traditional two way powder feeding mode, and the powder feed rate can be adjusted in real time through the parameters, so as to greatly improve the material utilization rate.